Aaron Cato, Associate Professor and Extension Specialist in Horticulture IPM, University of Arkansas

Sprayer selection can be a pivotal factor in achieving good and thorough spray coverage. Although spray volume tends to have strict requirements based on canopy size, good coverage can be achieved in dense canopies using forced air without increasing spray volume. However, air blast sprayers do best in larger applications with more vertical canopies, whereas crops like strawberries with compact and dense canopies are still primarily sprayed without forced air outside of Florida and California.

Many growers in the Southeast are currently exploring the use of air blast and drone sprayers in strawberries to save on cost and reduce tractor travel through fields that are often muddy from spring rainfall events. Although multiple rows can be sprayed in one pass, it is likely that the uniformity of spray patterns will decrease compared to nozzles directed into the canopy. In the same vein, air blast sprayers are unlikely to reduce the necessary spray volume. Many berry growers are also considering the use of drone sprayers in small fruit crops, such as strawberry, to avoid rutting up fields in wet periods, but their value remains uncertain. For both air blast sprayers and drone sprayers, it’s likely that uniformity of spray applications could be much lower than boom sprayers, as material would be much more affected by wind as the material travels a larger distance to the plant.

Strawberry Spray Volume and Sprayer Trial

In the fall of 2024, we established a strawberry trial in northeast Arkansas to compare the effectiveness of boom/hoop, drone, and air blast sprayers in an annual plasticulture strawberry production system. For each sprayer, we tested at least two different spray volumes, with lower volumes explored in the drone sprayer due to the small spray tank and limitations of batteries (Table 1). It is important to note that 40 and 20 GPA would be expensive to achieve using a spray drone over several acres, primarily due to the large number of flights and charged batteries needed with a 10-gallon spray tank. Plots had three rows side by side. When using a DJI T-50 drone sprayer, applications were made to three rows in one pass. With the air blast sprayer, spray was applied across three rows via a pass down each side of the three-row plot. The boom sprayer had four directed nozzles and traveled one row at a time, necessitating three passes per plot. Shared below are preliminary data from a fall application about 45 days after planting ‘Ruby June’ plug strawberry plants (Figure 1). Two spray cards measuring 3 ft in length were placed in each of the three rows, with data primarily shared from the in-row spray card.

Table 1

Sprayers and spray volumes applied to strawberry plants on 11/15/2024, 45 days after planting plug plants.

| Drone Sprayer | Air Blast | Boom Sprayer |

|---|---|---|

| 40 GPA | 100 GPA | 100 GPA |

| 20 GPA | 60 GPA | 60 GPA |

| 10 GPA |

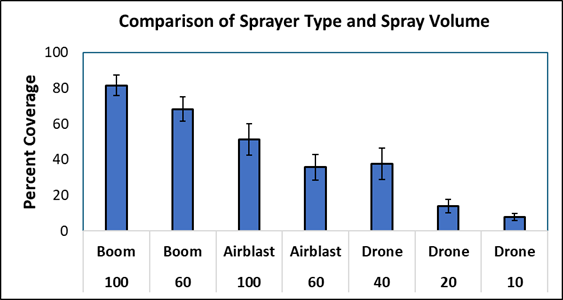

Data from this trial indicate that the boom sprayer achieved much higher coverage than all other sprayers. A boom sprayer at 60 GPA even achieved higher coverage than 100 GPA with an air blast sprayer (Figure 2). However, acceptable coverage when considering percent coverage alone was achieved by all sprayer and volume combinations except the drone at 20 and 10 GPA. Acceptable coverage is typically achieved when spray cards are above 15% covered with droplets, with at least 20-25% coverage preferred in strawberry.

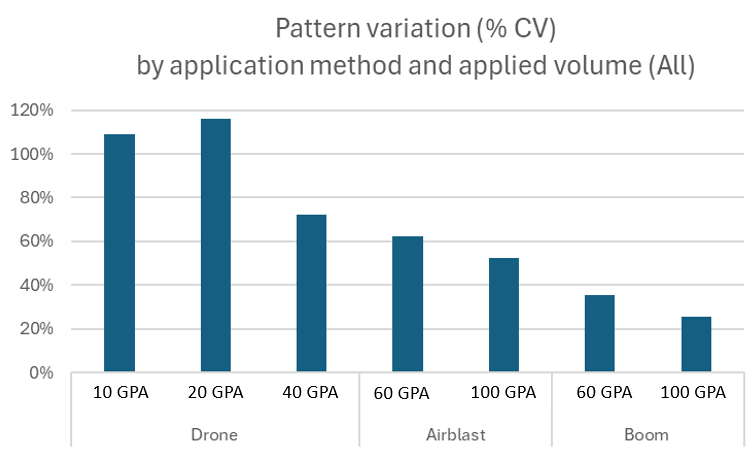

When considering spray pattern variation, higher spray volumes tended to have more uniform spray patterns, and boom sprayers had much lower variation compared to air blast or drone sprayers (Figure 3). Even at wind speeds between just 3-6 mph, air blast sprayers applying spray from both sides of a three-row plot resulted in twice as much variation in spray coverage, compared to boom sprayers applying spray to each row individually. Drone sprayers exhibited two to three times more variation than the boom sprayer. The issue with variation is that pathogens can multiply in the regions that aren’t covered. Anyone who has dealt with anthracnose fruit rot knows that one small outbreak can quickly snowball into an epidemic in the right conditions.

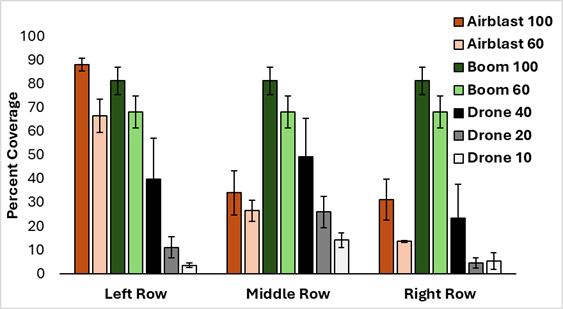

When data from spray cards placed in each row were analyzed separately, we saw a consistent pattern (Figure 4). Air blast sprayers more heavily applied material to the left row, whereas we observed higher coverage directly below and to the left of the drone’s flight path. It could be asked whether more forced air could be used to even out spray material to all three rows with the air blast sprayer, or whether the differences in the drone would even out across the whole field, but more forced air would likely just have resulted in lower coverage overall. Spray material was easily reaching all rows and any more punch would have blasted too many droplets off into the air to evaporate. Instead, the issue was simply down to very minor wind gusts of just 5 mph completely shifting almost all spray material to one side of the plot for periods of time. We would likely not see that even out completely across a field.

Conclusion

Work with sprayer type and volume is ongoing in Arkansas this summer and we hope to share more data soon. We continued this strawberry trial and applied 11 springtime fungicide applications with the air blast and boom sprayers, and we’re excited to see if that led to any differences in fruit rot or yield. What we have learned from these trials is that there is a lot of risk involved in jumping headfirst into new technology or tactics to save time when it comes to protecting small fruits with pesticides. My recommendation would be to find an ideal spray volume for your operation and crops and use spray cards to make sure you are evenly applying spray to the canopies. While air blast sprayers are the mainstay in crops with large plants, I don’t suspect that they do an adequate job covering the back sides of strawberry plants not directly in the line of fire. With diseases like Neopestalotiopsis leaf, fruit, and crown rot cropping up and necessitating good coverage of the crown, I would hesitate to use any sprayer that isn’t directly pushing spray material into plants and directly on all fruit. We’d like to thank Max Drone Service for being very interested and willing to help us with this research.

As always if you have any questions feel free to give me a call (Aaron Cato, 479-249-7352. If you are interested in building a cheap strawberry sprayer, check out our YouTube channel.