By David Gadoury (Cornell University) and Natalia Peres (University of Florida)

Microbial pathogens that attack the above-ground parts of plants live in a world that is bathed in sunlight and have done so for nearly 300 million years. In that time, these simple one-celled microbes have evolved to sense, use, and interpret light to direct their development. One component of natural sunlight is in the shortwave ultraviolet part of the spectrum. The shortest of these wavelengths that reach the Earth are harmful to cells of many organisms, and if you are one-celled, well then you just don’t have a lot of cells to waste. Shortwave UV from the sun causes subunits of the pathogen’s DNA to bind together so that instead of a genetic code, it is genetic babble.

This presents a challenge to microbial pathogens; one to which they evolved an ingenious solution: a photolyase enzyme that can undo the damage caused by UV to their DNA as fast as it occurs. The “photo” part of photolyase refers to its requirement for light to drive the biochemical repair process. The repair process requires another part of the solar spectrum: blue light. Because there is neither UV nor blue light at night, the repair mechanism does not operate in the dark.

And that last fact is the key to using ultraviolet light as a means to suppress plant pathogens. When used at night, we bypass the pathogen’s ability to repair damage to its DNA, and we can kill a pathogen (and even some insect and mite pests) with a relatively low dose of UV that is harmless to a multicellular organism like a plant. Our work on UV for control of plant pathogens has been developed by an international, multi-disciplinary, and multi-institutional group that collaborates to bring this technology to bear for several food crops.

Strawberries were one of the first crops where the nighttime UV technology was delivered in a manner that was practical for field production. We chose the powdery mildew pathogen (Podosphaera aphanis) as the target. Powdery mildew is primarily an external parasite, so it occupies an exposed niche. There were certain requirements for a device to deliver the required UV dose in an effective manner. It would need to be powerful enough to deliver the UV to the plant at a speed sufficient to cover significant acreage in a single evening. It would also have to do so uniformly on a target that was architecturally complex: all of the exposed surfaces of a multi-layered canopy of a strawberry plant. We settled on a hemicylindrical array of low-pressure discharge UV-C lamps backed by polished aluminum reflectors (Fig. 1). This array could be configured to diverse plant canopies by altering its height, width, and length, and it could be moved as a tractor-drawn device or by a fully autonomous robotic carriage.

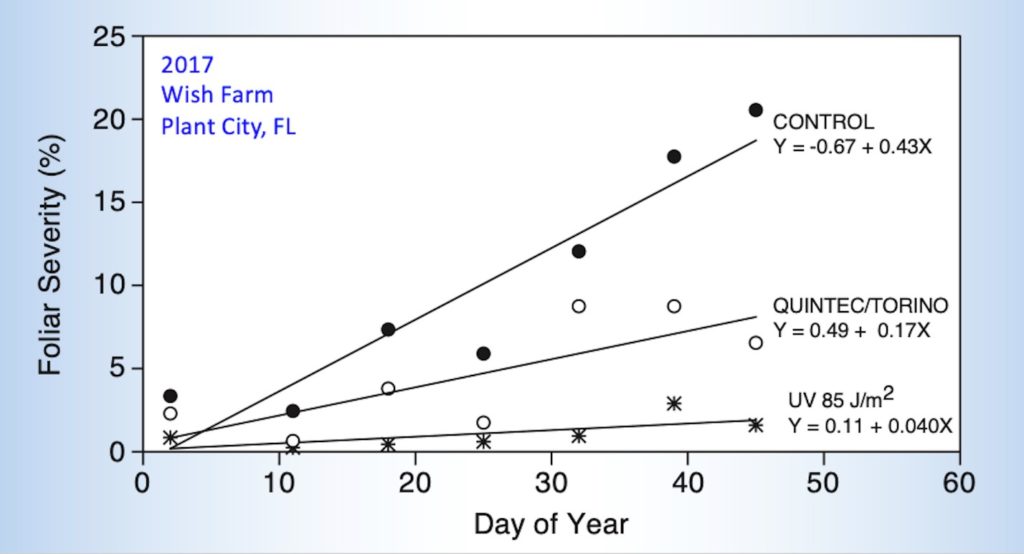

Trials in commercial strawberry fields in Florida began during the 2016-17 growing season. UV applications of up to 200 Joules per square meter were applied 1- to 2-times per week to a highly-susceptible variety that received no other fungicides for suppression of powdery mildew. UV treatments in general produced excellent suppression of powdery mildew. In fact, usually better than that provided by the best-available fungicide (Fig. 2). Trials in multiple locations in the US and Europe have duplicated these results.

Some of the most intense interest in UV technology comes from strawberry nursery operations, where UV presents a promising method to suppress powdery mildew on transplants without exposing the surviving isolates to selection for resistance to fungicides used in the fruit production fields. This has always been a conundrum of commercial strawberry production. There are relatively few modern fungicides that do not present a risk of resistance. The more you use them, the greater the risk. So, how does one preserve them for the greatest good? UV offers a non-chemical means to effectively suppress powdery mildew in nursery operations without risk of resistance. UV technology has been used for over 75 years in various microbiological applications, including hospitals, water purification, and food processing, with no reported examples of practical resistance. At least one commercial nursery in Nova Scotia has applied the UV technology on a grand scale, building the largest UV array developed to date (Fig. 3) and using it.

Nighttime UV technology has now shown activity against several powdery mildews of other crops, including grapevine, cucurbits, rose, basil, and rosemary; as well as suppressing plant-feeding mites. Most recently, it has shown surprising activity against a bacterial disease of apple (fire blight), a severe leaf blight of beets (Cercospora leaf spot), as well as sour rot on grapes, and some mild suppression of gray mold (Botrytis cinerea) on strawberries. Detailed examinations of the physiology of UV-exposed plants have not detected any harmful effects at the doses used to protect them from harmful pathogens or pests. Likewise, populations of harmless microbes on the surfaces of UV-treated plants seem to rebound rapidly after treatment, perhaps because the UV treatments leave no suppressive residue to prevent recolonization.

The nighttime UV technology is flexible, adaptable, and scalable. Plans to build towable arrays are available and could be constructed by anyone with appropriate skills in fabrication. In addition, there are companies that produce autonomous robotic arrays that can either be purchased or contracted as a service. As we gain experience in multiple crops, we are also training the scientists and end-users to develop the human capital that will hopefully sustain the technology as it develops.

Acknowledgments

This research was primarily supported by the USDA Organic Research and Extension Initiative award number 2015-51300-24135, with additional support from the Florida Strawberry Growers, Wish Farm Strawberries, Fancy Farm Strawberries, Driscoll’s Berries, the New York Wine and Grape Foundation, John Martini at Anthony Road Wine Company, and Greg and Lillian Taylor at Bully Hill Vineyards, and Saga Robotics LLC, Drs. Collaborators included Mark Rea and Mariana Figueiro of Mount Sinai Research Hospital, Drs. Arne Stensvand and Aruppillai Suthaparan of the Norwegian University of Life Sciences, Dr. Jan Nyrop at Cornell University, Dr. Lance Cadle-Davidson of the USDA Grape Genetics Research Unit, Dr. Rodrigo Onofre of Kansas State University, Dr. Michelle Moyer at Washington State University, and Dr. Walt Mahaffee, USDA-ARS, and finally to the late Alfred J. Michaloski, who first approached us with a crazy idea that germicidal lamps might control grape powdery mildew in 1991 (see US Patent Number 5,040,329).