Aaron Cato, Associate Professor and Extension Specialist in Horticulture IPM, University of Arkansas

Small fruits grown in the Southeast face significant challenges posed by pests due to our warm and humid climate. Nailing down an effective rotation of fungicides and insecticides to prevent fruit yield and quality loss is a necessary and difficult endeavor that will decide your farm’s success. What is often overlooked on many farms is the application process. Although you may perfectly select a pesticide and spray it at the optimal time to minimize injury or disease, if the pesticide is not adequately covering the sensitive plant material, it may not work at all!

Spray Volume

Whether your crop is adequately protected depends on your choosing the right spray volume for your operation and, to a lesser degree, the right sprayer. One thing I always tell growers to consider is how much foliage you need to cover. Although 15 gallons per acre (GPA) of spray volume may be acceptable for an acre of soybeans, will the same amount of water spread evenly across an acre of 6-7 ft tall blackberry or blueberry plants? Increases in spray volume will help to more evenly disperse spray material across the canopy and can help access regions of dense plant canopies that are the epicenters of disease outbreaks. Minimum volume will vary by small fruit crop and may be a bit different for each operation. Crops like blackberry, grape, and blueberry often get adequate coverage at 50-60 GPA with an air blast sprayer, but many pesticides, such as Sulforix or horticulture oils, will require upwards of 100 GPA for success. Strawberries sprayed without air assist tend to require 80-100 GPA, as larger droplets and extra runoff of spray material from leaves help penetrate dense, compact canopies.

Spray Volume Trial in Blackberry

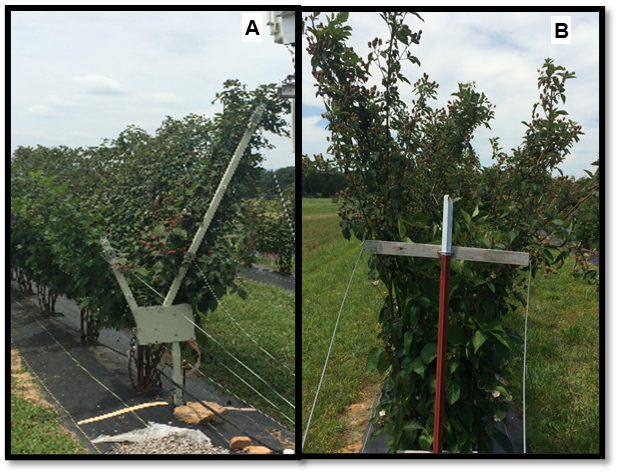

One factor that affects necessary spray volume is the production or trellis system that is being used. Trellis systems can change the canopy density or structure and impact coverage of spray applications. Previous research on blackberry trellises with reduced canopy densities indicated that the changes in canopy architecture led to reduced humidity and increased ambient temperature compared to denser canopy trellis systems, such as the T-trellis (Figure 1). The rotating cross-arm (RCA) system consists of a flat plane of floricanes that are separated from primocanes. This likely increases the efficiency of spray volume traveling through the blackberry canopy. An increase in spray volume efficiency could lead to better coverage on berries and reduce the incidence of spotted wing drosophila (SWD) infestations. We investigated the spray volume (GPA) necessary to achieve acceptable coverage in an RCA production system with a blower sprayer using water-sensitive spray cards. We also investigated pest complex differences between RCA and T-trellis systems. This work was funded by the Southern Region Small Fruit Consortium in 2021. For more information regarding the methods and nuts and bolts of this trial see our final report.

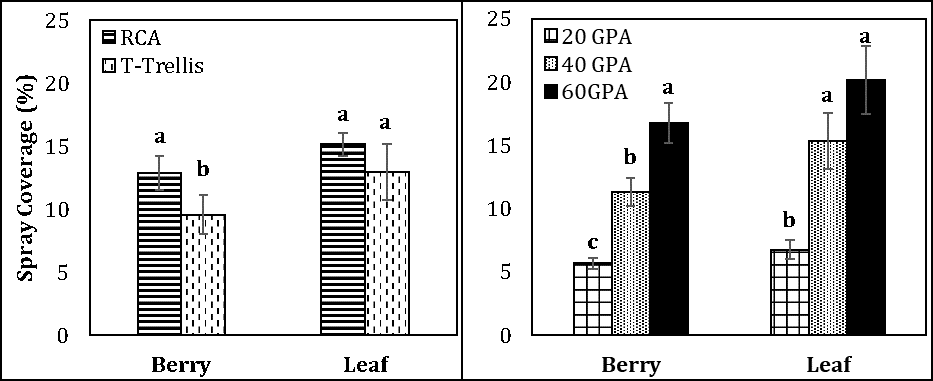

Increased spray coverage was observed on berries on the RCA trellis system (13%) when compared to the T-trellis system (less than 10%) (Figure 2). We also observed a significant reduction in spray coverage of berries as our spray volume decreased, with 60, 40, and 20 GPA providing 17%, 11%, and 5% coverage, respectively (Figure 2). Considering that 15% coverage is usually our goal, delving too far below 60 GPA could affect efficacy fast. We did not see an interaction between the trellis and spray volume treatments. We did observe more SWD larvae on the T-trellis compared to the RCA trellis, but did not observe a significant impact of different spray volumes.

Spray Volume and Trellis with Drone Sprayers

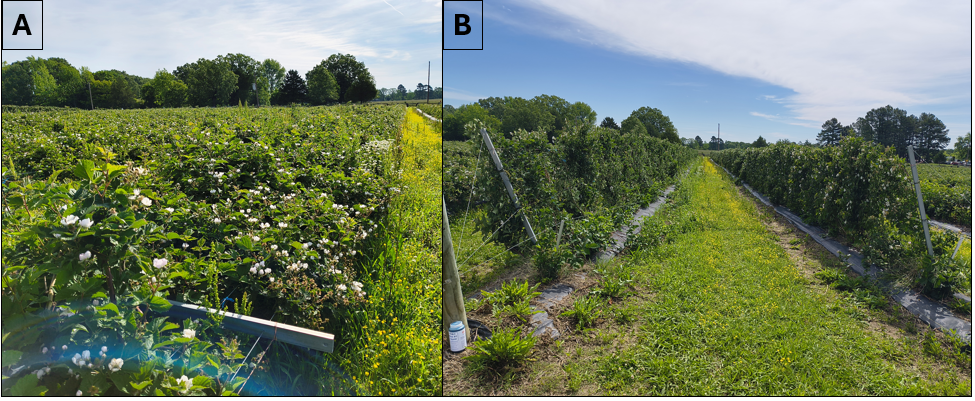

Another question we often get is about the feasibility of drone sprayers in crops like blackberry. Previous research has shown poor coverage in a T- or V-trellis at the spray volumes feasible for drone sprayers (likely 3-10 GPA). However, we sought to better understand whether providing adequate coverage could be more feasible with a trellis like the RCA, which has a much thinner canopy. The fruiting canopy is laid almost parallel with the ground in the down position, seemingly making it an easy target for a drone sprayer flying overhead. In addition, anyone who has ever used the RCA trellis knows that spraying during flowering, when the trellis is in the down position (Figure 3), is a pain due to the cost of picking up the trellis to get a tractor down the row to spray it. We sought to determine whether a drone spray could fill this niche and avoid the need to stand up the trellis. We also compared the coverage provided by a drone sprayer to plants on a V-trellis and on the RCA in the upright position (Figure 3).

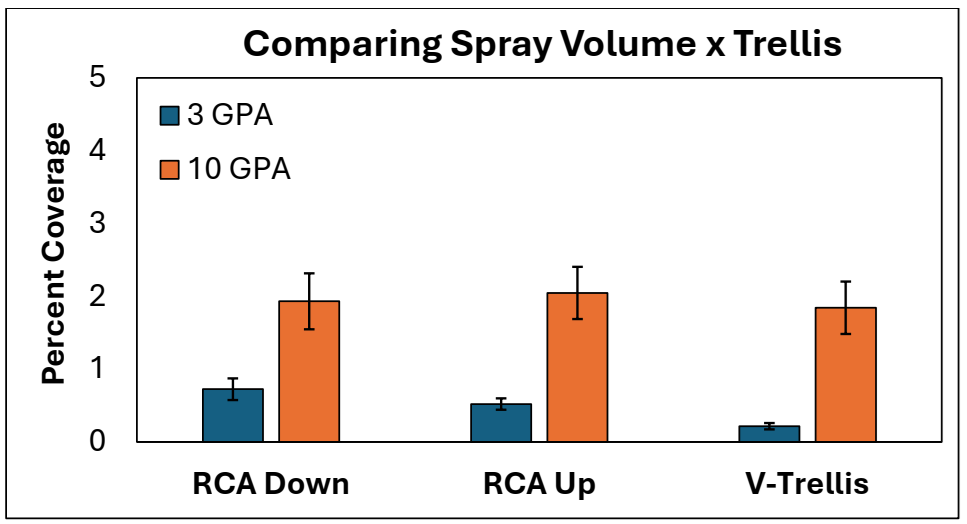

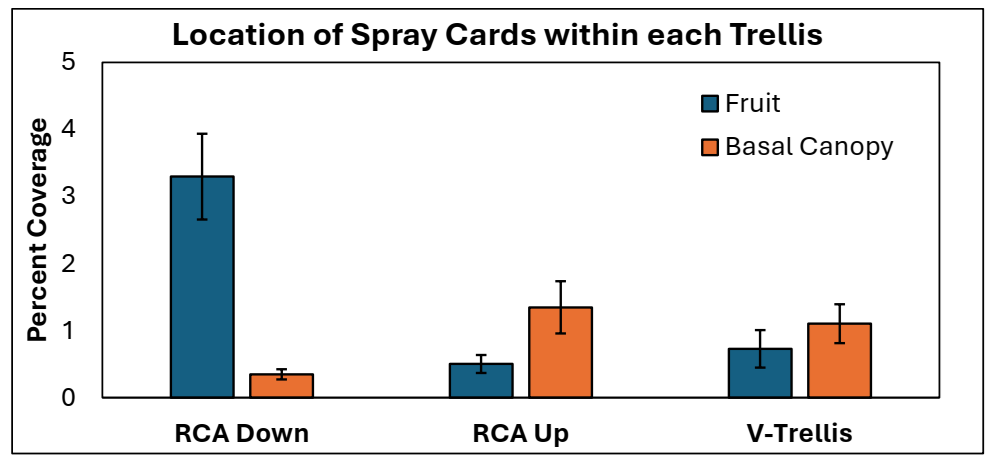

We placed spray cards in several areas of the canopy of each trellis and ran flights with a DJI T50 drone sprayer at two spray volumes for the RCA in the up and down position, as well as for the V-trellis. We did not observe an interaction of trellis and spray volume, although the V-trellis seemed to be a bit harder to cover at 3 GPA vs. 10 GPA (Figure 4). Ultimately, 2% spray coverage across the trellis is unacceptable. However, there were some major differences regarding what areas of the canopy were being covered. Comparing data from cards placed near the fruit vs. in the basal canopy (between the bottom wire and second wire), we observed stark differences in coverage (Figure 5). Here, we did observe a significant interaction between spray card location and trellis, with a very large difference in fruit and basal canopy coverage when the RCA was laid down. We expected the fruit and flowers to be an easy target for the drone sprayer, and we did see more coverage here, although it was still less than desired.

Ultimately these data show that the RCA may still offer some benefit from a thinner canopy when using a drone sprayer, but an air blast directing material directly into the entire canopy still reigns supreme. Although no acceptable coverage in any canopy location was reached at 10 GPA, it is possible that a drone applying at 20 GPA could effectively cover the flowers of RCA blackberries in the down position. The problem is that you likely would not be covering your primocanes at all. If you were hoping to protect them from a litany of leafspot diseases or anthracnose, you’d miss that protection with a drone. There’s still a lot of work to be done in this area of study, and we’re hopeful drones will become more efficient. We’d like to thank Max Drone Service for being very interested and willing to help us with this research.

Conclusions

Ultimately these data showcase two important factors relevant to pesticide success on your operations. Too little spray volume will lead to unacceptable coverage. We know that this can increase your risk of pest outbreaks and ultimately decrease the efficacy of your selected pesticides. We recommend 50-60 GPA in blackberry with an air blast sprayer, and our data show that to be the sweet spot for getting around 15% coverage of sensitive portions of the plant, which is ultimately what we shoot for. Second, the spray volume you should use on your operation was not written on a stone tablet and brought down off Mt. Sinai. Our work clearly showed that production systems will impact your needs. Ultimately you should take canopy density and estimations of coverage using spray cards into consideration when determining what is acceptable. This needed spray volume is likely to change throughout the year as plant canopies change. This is especially relevant to annual crops like strawberry. Ultimately your pesticide label requirements for spray volume should always be your minimum, regardless of what we may deem necessary.

For more information, contact Aaron Cato at 479-249-7352.